Centering and Shuttering / Form Work

Shuttering or form work is the term used for temporary timber, plywood, metal or other material used to provide support to wet concrete mix till it gets strength for self support. It provides supports to horizontal, vertical and inclined surfaces or also provides support to cast concrete according to required shape and size. The form work also produces desired finish concrete surface.

Shuttering or form work should be strong enough to support the weight of wet concrete mix and the pressure for placing and compacting concrete inside or on the top of form work/shuttering. It should be rigid to prevent any deflection in surface after laying cement concrete and be also sufficient tight to prevent loss of water and mortar form cement concrete. Shuttering should be easy in handling, erection at site and easy to remove when cement concrete is sufficient hard.

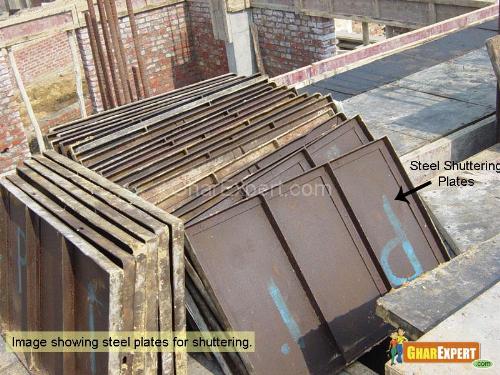

Steel plates for Steel Shuttering

Generally there are three types of shuttering.

- Steel Shuttering

- Wooden Planks Shuttering

- Temporary Brick Masonry Shuttering

Steel Shuttering

Steel shuttering plate is the best type of shuttering because this is water tight shuttering which can bear the load of cement concrete placed on it. This shuttering can be used for horizontal, vertical or any other shape required for the work. It gives leveled surface which has good appearance. This shuttering gives good appearance and pattern work according to architectural drawings. If the plaster is required, the thickness of plaster will be less. Being water tight shuttering, the strength of concrete with steel shuttering is comparatively higher.

Shuttering with the help of Steel Plates.

Note: As this is water tight shuttering, it is considered the best shuttering.

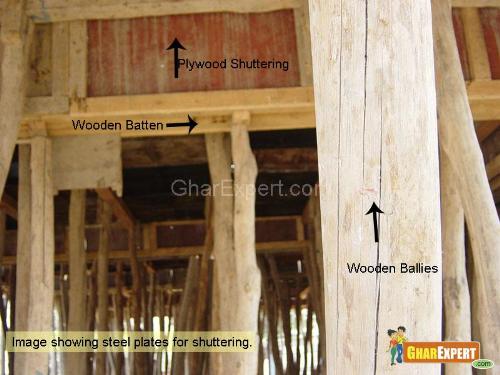

Wooden Plank Shuttering

Generally wooden planks shuttering is used by contractors because this shuttering is cheap and easily available. But this type of shuttering effects the strength of concrete and have some disadvantages which are given below.

Disadvantages

- This is not water tight shuttering as the size and thickness of planks differ and are not of same size. Due to this difference the water and cement flow to the ground from joints and reduce the strength of concrete.

- Bottom level of RCC slab is not in straight line and the surface being uneven, the thickness of plaster is more which remains weak.

- Due to leakage of cement slurry through joints, earth work below ’'Ballies’ may settle and create problems.

- In some cases wooden planks can not bear the weight of concrete. Due to low strength there is bending or deflection in wooden planks. Sometimes the planks may break.

Shuttering done with the help of wooden ballies and batten.

Temporary Brick Masonry Shuttering

In some cases labor contractor uses Temporary Brick Masonry in mud for vertical support of sides of beams, fascia etc. This shuttering should be avoided. This type of shuttering reduces the strength of cement concrete by soaking cement slurry. Also no proper compaction is made as this shuttering does not bear the pressure of vibrator. The surface of cement concrete given by this type of shuttering is uneven and the thickness of plaster is increased.

Precautions for Vertical Supports for RCC Beams, Slabs etc

- The ’'Ballies’ used for vertical support should not be less than 6'' dia and these should be in one length without joints.

- Never allow bricks support of more than one or two bricks below a 'balli' to make required height.

- Cross Ballies or bracing should be done for better support to beam as well as slab.

- The wooden batten used below the plate should not be less than 5'' in height.

- At the time of concreting one carpenter with helper having spare ballies, nails etc. should be deputed for watching any disturbances in ballies under shuttering.

Precautions for Cantilever slabs and Beams

- While doing shuttering of a cantilever part, outer edge of shuttering is 1” to 2'' higher than inner edge with the wall.

- The bracing of vertical supports for cantilever portion should be tied to vertical supports of internal slab.

- The concrete should be laid on cantilever portion very gently.

- The shuttering should be removed after 28 days.

Recommended Period for Removal of Shuttering

- 48 hours for sides of foundations, columns, beams and walls.

- 7 days for underside of slab up to 4.5 meter span

- 14 days for underside of slab, beams, arches above 4.5 meter up to 6 meter span.

- 21 days for underside of beams arches above 6 meter span and up to 9 meter span.

- 28 days for underside of beams arches above 9 meter span.

Defects Found In Shuttering/Form Work

- The supports of form work are not in plumb and are not cross braced.

- The ground supports of ballies are poor and therefore settle the form work.

- There is insufficient thickness of shuttering plates/planks unable to bear lateral pressure imposed by wet concrete especially in columns.

- Shuttering plates are not cleaned and oiled or oiled with dirty oil.

- There are many insufficient and loose connections in centering and shuttering.

- The form work is removed before time. The work is not planned and designed properly.

- In case of beam shuttering proper provision for retaining side is not made. Hence the side of beam is not in proper line.

- The shuttering is poorly made with cracked and warped timber planks having lots of holes and knots.

- Through bolts for RCC walls form work for an underground tank is used. Later these holes made by bolts are not plugged.

- ‘Ballies’ are resting on bricks or brick pillars

- Ballies are not in one piece. Small ballies are used and these are not properly jointed. Also no additional cross bracing is provided at the joint.

- The supports under shuttering plates are not properly tight.

- The earth work under supports is not properly compacted before starting shuttering work.

- The bottom of ‘ballies’ are in wedge shape, not having proper base.

In the construction of building work, there is need of various types of building materials which are used during the construction work at different stages. According to structural drawing, cement concrete of different qualities or mix are used in the building at different stages according to the type of building.

In the construction of building work, there is need of various types of building materials which are used during the construction work at different stages. According to structural drawing, cement concrete of different qualities or mix are used in the building at different stages according to the type of building.

100% FLY ASH AND CRUSHED WASTE GLASS

100% FLY ASH AND CRUSHED WASTE GLASS

Now you can construct your home/ building utilizing modern technology, known as ready mix concrete which not only creates a strong building but also helps in providing ease at work/site. This article tells you about ready mix concrete, preparation of ready mix concrete and its benefits.

Now you can construct your home/ building utilizing modern technology, known as ready mix concrete which not only creates a strong building but also helps in providing ease at work/site. This article tells you about ready mix concrete, preparation of ready mix concrete and its benefits.

Mild steel bars in reinforced concrete are one of the exceptional building materials. Reinforced concrete requires very strong steel bars. This article provides a brief view of steel bars in cement concrete work.

Mild steel bars in reinforced concrete are one of the exceptional building materials. Reinforced concrete requires very strong steel bars. This article provides a brief view of steel bars in cement concrete work.

Kota stone flooring is a subtle blend of grandeur and luxury giving the interior and exterior a gorgeous look.......

Kota stone flooring is a subtle blend of grandeur and luxury giving the interior and exterior a gorgeous look.......

To get maximum ventilation and natural light in your house, make sure the building is properly oriented. Orientation of building saves energy and provides comfortable living as well. This article tells you about various factors and benefits of building orientation.

To get maximum ventilation and natural light in your house, make sure the building is properly oriented. Orientation of building saves energy and provides comfortable living as well. This article tells you about various factors and benefits of building orientation.

Preview some of the most impressive pictures of kitchen from GharExpert Gallery.

Preview some of the most impressive pictures of kitchen from GharExpert Gallery.

A solid roof on building is very important for everybody living in the house. The roof should be constructed in a way that assures you great safety. Here are given details about different types of roofing.

A solid roof on building is very important for everybody living in the house. The roof should be constructed in a way that assures you great safety. Here are given details about different types of roofing.

Frames of doors and windows are most important parts of your doors and windows. They are available in different size, height, width and shapes. Frames hold locks and hinges and support door and windows to shut and open easily. Here is what you need to know about different doors and windows frames.

Frames of doors and windows are most important parts of your doors and windows. They are available in different size, height, width and shapes. Frames hold locks and hinges and support door and windows to shut and open easily. Here is what you need to know about different doors and windows frames.

Elevation of Form house

Compact kitchen plat form with storage

Compact kitchen plat form with storage

Window in a picture form

POP Ceilling, Pillar work at entrance, Stone work on wall Professionalism

Steel Shuttering

Plywood Shuttering

Plantation Window Shutters

sliding shutter gate

FRP column shuttering

Wardrobe with profile shutters & lacquered glass

Wardrobe made with aluminium profile & laquerred glass shutters with sensor lights on top pelmet

Wardrobe with panelled shutter & sensor lights

Kitchen wall cabinet with etched glass shutter

Rolling Shutter

Creative window shutters

dual coloured shutters

wall paper on wardrobe shutter

shutters

Ludo Luck Center

Kitchen wall cabinet with etched glass shutter

Wardrobe with profile shutters & lacquered glass

Wardrobe made with aluminium profile & laquerred glass shutters with sensor lights on top pelmet

Wardrobe with panelled shutter & sensor lights

Steel Shuttering

Plywood Shuttering

Plantation Window Shutters

Teakwood center table

Center Table concept design 1

living room center tabil

STUDENT CENTER

INTERIOR VIEW OF STUDENT CENTER

Bronze and Glass Center table

Wall shelves and center table design

Ground Work

Simple Living room with TV unit, Center table and sliding door design

brick work and truss

staircase centering

Modern sofa and center table in leather

Modular kitchen design with cook top and hood at the center of the kitchen

Nice Center Table

work in progres

Wooden center table design

Tradionally painted work on ceiling

Modern Center Table Design

Center of POP ceiling design

Wooden center table with glass top

Rectagle shape center table

Steel Bars For RCC Work

inlay work in flooring

glass work

Stylish Center Table

Ceiling with wood work

false ceiling dome for center of a room by maqbool interior

Creative window shutters

glass work

Center table design

Computer work Station

Exterior view of house under Construction work

Stone work on walls

Low height center table design

Center Table

office work

Center table

glass work

Nice Brick Work

Brick Work On DPC

Work in Progress

Cement Concrete and Brick Work in Foundation of Wall

wood work